A unique encounter with April's Birthstone: Diamond

Last year I spent day at Royal Coster Diamonds in Amsterdam learning how to polish diamonds with my good friend (and pop-up shop co-host) Melindi.

Private viewing

Our wonderful tutor for the day, Frank, started by showing us some incredible examples of diamonds!

The diamond shape you'll be most familiar with is the round 'brilliant' cut. It has 58 facets as shown on this diagram:

But back in 2007, Royal Coster developed a new 'brilliant cut' called the Royal 201, because is has an incredible 201 facets and sparkles like nothing you've seen before!

Frank told us it can take 3 full days to hand cut a Royal 201 diamond, so as you can imagine they are extremely valuable!

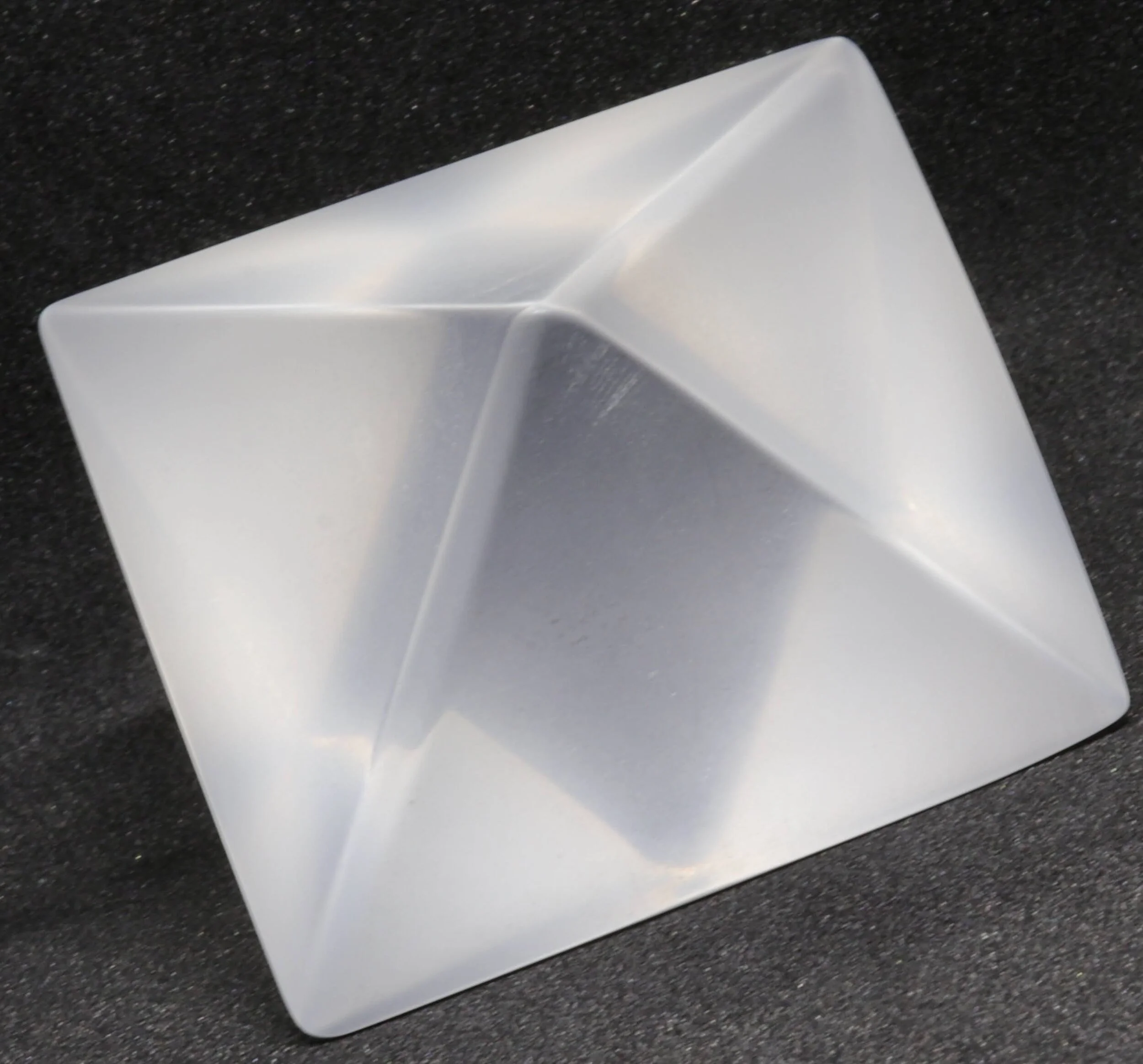

The slides below show a great example of the transformation from natural rough diamond crystal shape to finished brilliant cut stone.

From natural crystal to cut diamond.

Here’s a .gif of an amazing Royal 201!

Diamond Museum

Onto our tour of the diamond museum - which featured the history of diamond discovery, mining and trading - we heard about the 4 Cs of diamond valuation (Cut, Colour, Clarity and Carat) and saw replicas of many famous crowns that Royal Coster created for Royal houses worldwide - Including the Ugandan King of Buganda’s crown, which happens to be the tribe on Melindi’s birth certificate!

Other interesting exhibits included:

A copy of the famous 109ct Koh-I-Noor diamond (the main stone in the British Crown Jewels), which Queen Victoria had repolished by a team from Coster Diamonds in 1852

A signed print of Damien Hurst’s For The Love of God encrusted skull. (silkscreen print with diamond dust)

A glittering diamond monkey skull - set with 17000 brilliant cut diamonds

A diamond identifying quiz - a row of rings containing various simulated diamonds* and one real diamond ring (luckily I chose the right ring)!

*simulations including glass, cubic zirconia, moissanite, white sapphire, spinel.

Diamond Faceting

The afternoon was spent at the polishing table, attempting to polish facets into a diamond! A rotating disc covered in diamond dust is used to hand polish diamonds. Here you’ll see a diamond held in a vice. The arm of this vice allows you to control the angle at which you move the diamond over the polishing disc. Each time you push the diamond over the disc you then have to check the cut and look for any inclusions just under the surface using a 10x magnifying loupe.

One facet probably takes hundreds of passes over the disc. Our forearms bloody ached after a couple of hours of polishing, I’d burnt the tip of my finger on the hot diamond and we’d just about managed 2 facets each …

We absolutely loved the experience and were each given a Royal Coster brilliant cut diamond and a 10x Loupe as momentoes of the day!

The culet (pointy tip) of the diamond is visible at the end of this clamp.

The shiny half moon shape is the first facet being cut on the crown (angled top) of a diamond.

We celebrated our newfound skills with a rewarding drink in a cool bar just down the road!

A big thank you for Frank Van Poorten and Royal Coster Diamonds for the images, information and a fabulous day!

Diamonds

I love diamonds and the sparkle from a nice diamond is mesmerising. But as you know I’m a coloured gemstone lover, so I like to use diamonds in my designs to emphasise the beauty of a coloured stone.

You’ll see a few of my designs have a diamond halo around a centre gemstone. These stones flash with light and focus attention back on the centre stone to create interest and draw people’s gaze to your jewellery.